What hand tools do I need to start woodworking? - Part 3: Planing and shaping

So you’ve measured and marked out your timber, and maybe used some saws to cut it to the sizes you need, but how do we shape and smooth timber from this point? Planes, spokeshaves, rasps and files are tools we reach for all the time in our classes and our own workshop, and a well tuned hand tool can quickly and simply do the job of a power tool with a lot less noise, dust, and even time!

Bench planes

Planes are tools for removing timber in an even and controlled way.

The body of the plane houses a wide, thin blade, and by carefully adjusting the position of the blade you can take nice, smooth shavings off of a piece of timber. Planes come in a range of sizes, named in order from smallest to largest from 1 through to 8. Chances are if you’ve seen a hand plane around, you’ve seen a number 3 or 4, which are the most commonly used sizes.

In the Among The Trees workshop we use a combination of metal and timber hand planes, both of which are still a useful and versatile tool.

You can buy high quality new hand planes from bespoke tool manufacturers, but if you’re looking for a standard hand plane for regular use, a vintage second hand plane is a tool to be trusted through thick and thin.

Spokeshave

Spokeshaves are another old-fashioned looking tool that is just as useful and functional today as it was 50 years ago. Named for their original use, shaving and shaping the spokes of cart wheels, a small, wide blade is housed in a body with long arms to either side.

Using these arms, you can control the angle of the blade against the timber with a high level of accuracy, and carve simple or complex shapes and curves in timber with just the feedback of the tool and the timber.

While metal spokeshaves are unparalleled for their convenience and ease of use, with a bit of practice a well honed timber spokeshave can do the job just as effectively, and they can often be picked up for a fraction of the price.

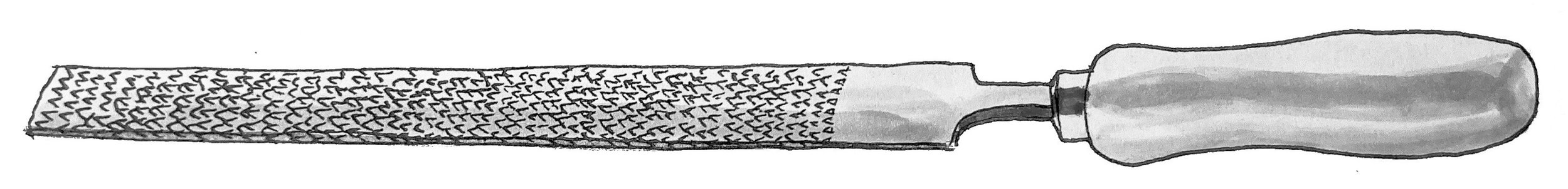

Rasps and files

Sometimes a single blade just won’t cut it, and we turn to the wonderful world of rasps and files. Rasps and files, while slightly different, are similar in design and function. A long metal surface, also known as the blade or face of the tool, is cut or ground with lots of metal cuts and ridges to create a serrated or stitched finish.

These sharp edges are then used to cut timber away from the surface in an even and controllable way. Rasps are used to take material off quickly, as they have larger teeth in the surface, whereas files are finer and will remove less material but leave a finer surface finish.

Rasps and files are also available in a range of cuts, such as rough cut and fine cut. By using a range of different cuts of tool, you can start by removing material quickly and effectively, and quickly work your way down to a fine surface finish.

Specialty planes

We’ve barely scratched the surface of the kinds of shapes and styles that hand planes can come in. Back before we had electric hand tools or machinery to do specific and detailed work for us, such as cutting rebates, routing out pockets, cutting channels and profiles, and more, there were planes that did these jobs for us.

At the Among The Trees workshop we have a growing collection of antique planes of all shapes and sizes, and encourage visitors and students to check them out and ask any questions you might have!

Learning more about planes, spokeshaves, and other shaping tools

If you’re interested to get some more hands on experience with the different kinds of planes that are out there, check out our short courses, including the 6 week Three-legged stool course or our one day Introduction to handplanes course or Australian hardwood rolling pin course, all of which have a range of different plane skills included.