How does a tree become a plank?

A tree is a beautiful thing. It can provide shade on a hot day, act as a windbreak during a storm, and be home to all sorts of wildlife. But for humankind, trees have been used most as a building material for houses, transport, furniture, and far more.

Once a tree has been cut down, the trunk is then cut into logs of manageable lengths. These are then transported to a sawmill, where they are split into flitches (a large plank or section of wood that is unfinished). How it is split will depend on the type of tree and what it will be used for. A flitch is then sawn into boards, which are then planed and cut to the desired size and shape.

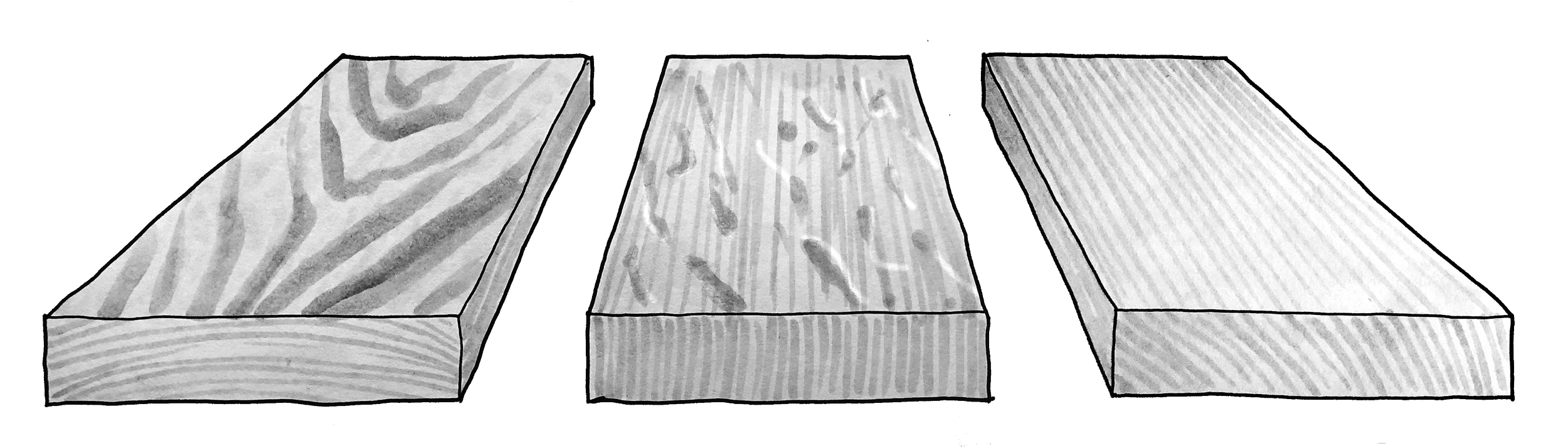

There are several different ways of sawing a log into timber, that each have different uses and strengths.

Quartersawn: The log is first sawn into quarters, then each quarter is separately sawn into boards. This method produces the most stable boards, with the most uniform movement over time. The downside is that it yields the least amount of useable lumber from a given log, since a lot of waste is generated in the form of sawdust and small pieces of wood.

Rift-sawn: The log is first split into quarters, then each side is sawed length-wise in an alternating pattern into boards. This method also produces stable boards, although not quite as stable as those produced by quartersawing. It yields more useable lumber than quartersawing, but less than plain-sawn or live-sawn methods.

Plain-sawn: After sawing into fletches, these are simply sawn lengthwise into boards with almost no waste. This method yields the most lumber from a given log, but the resulting boards are less stable and tend to warp and cup over time more than those cut using other methods. Live sawn logs are like plain sawn ones, but cut from one side of the log to the other.

From left to right: Plain sawn, quarter sawn, and rift sawn.

These boards are then either air-dried or kiln-dried, depending on the type of wood and its use, before being put onto the market. How the board has been sawn will affect how it dries, how much shrinkage occurs, and in which directions the boards shrink.

There are all sorts of different types of wood, each with their own unique properties. Some woods are strong and durable, others are light and easy to work with, while some have a beautiful grain that makes them perfect for furniture. When we think about the timber we buy, it's helpful to remember this process, and the amount of labour and energy that is used in every step of the process. Timber is a natural resource, but that doesn't mean it's an unlimited one. We need to be mindful of how we use it, and reuse what we can.

At Among The Trees, we work to save timber from landfill so it can be given a second life. We work with all sorts of companies and people to source wood that would otherwise be thrown away, so you can create beautiful, bespoke products from it. This means that each piece is completely unique, and has its own story to tell. If you're looking for something special made from timber, get in touch - we'd love to discuss your ideas!

Illustrations by Liz, © Among The Trees