Screws, nails & glue – when do I use what?

When you’re starting out with woodwork it can be a bit overwhelming looking at all the different fixings that are available on the market. You’ve got your timber dressed and cut to size by our friendly team ready for your beautiful new project, but there’s still some assembly to do – what should you use and why would you use one type of fixing over another?

Glues

Glues are arguably the most common way to fix two pieces of timber together. There are a wide range of glues, including:

PVA glue. This is the main modern type of wood glue you’ll see used. It’s widely available, easy to use, cleans up with water, and has a dry time that allows for fine tuning and positioning of glued surfaces once joined. When joining two long-grain surfaces that are well jointed and prepared, the glue join will be stronger than the timber itself – you can see this as glued-up timber often fails along a fault in the timber itself, not the glue joint. There are many types of PVA glue available and it’s worth finding one that will work for your purpose.

Hide glue/animal glue. Before synthetic glues, hide glue was the primary kind of glue available for woodwork. Hide glue can be made in the workshop as needed, or bought in a liquid form ready for use. Hide glue is often used when a glue joint needs to be reversible for repair or maintenance, as it will soften when heat is applied and is then able to be unstuck.

Cyanoacrylate/CA glue/superglue. CA glue has a reasonable amount of hold, and dries quickly and clear. However, it’s not recommended as a general woodworking glue.

Epoxy. We avoid using epoxy in our workshop where possible, but in some situations it is essential for a strong bond between materials where PVA or CA glue won’t hold with as much strength.

Glues, as well as other fixings, can be described by talking about their shear, axial and bending strength. Different glues will have different levels of strength depending on the type of pressure the joint experiences, and in what direction.

Keep tuned to our website to read more about different glues in a future blog post!

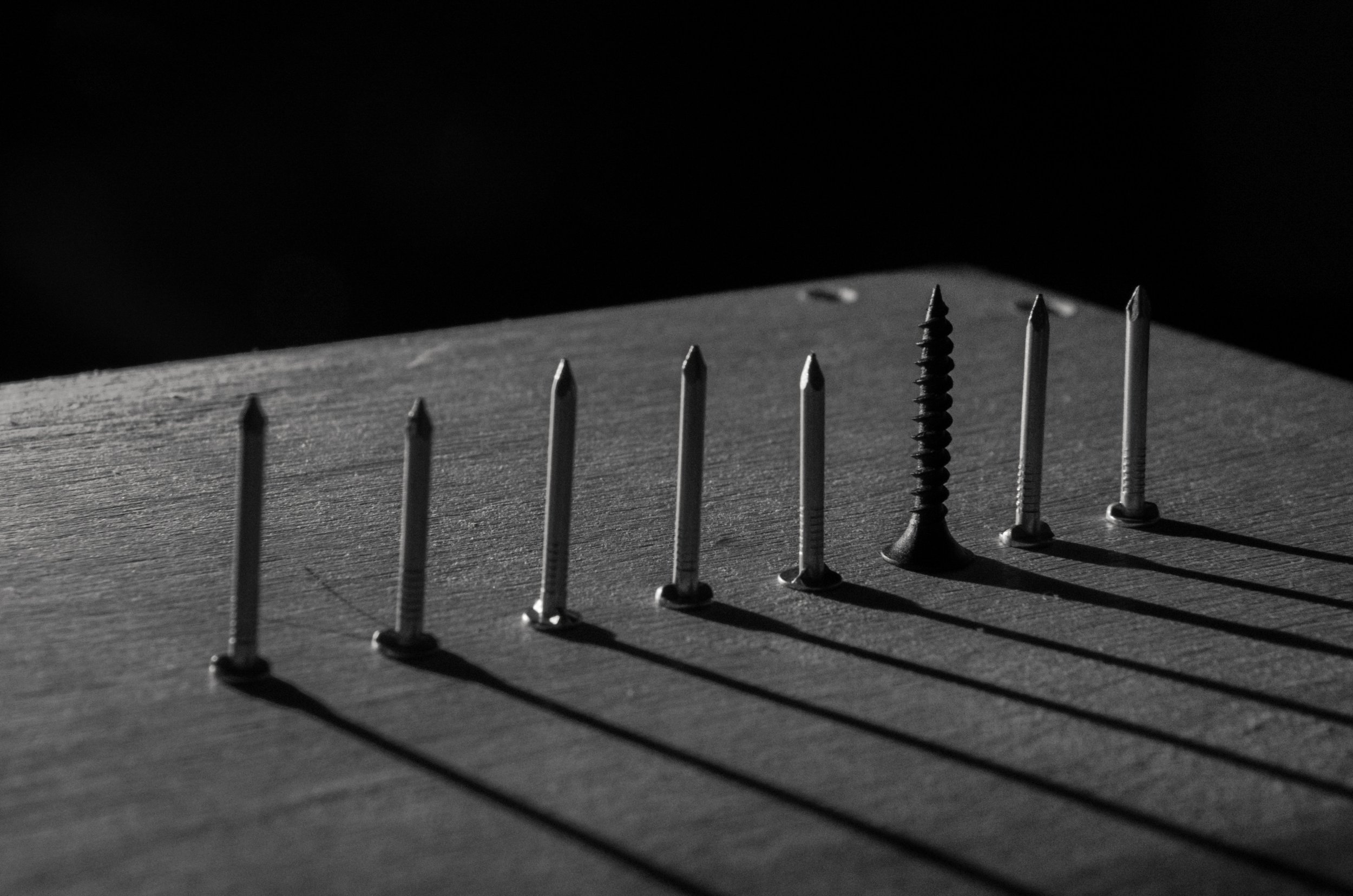

Screws

It may seem like stating the obvious, but a screw is a small fixing with a threaded shaft. It may include a threaded and/or bladed tip that can dig itself into timber as it is driven in.

Screws are often made of softer materials than nails, but make up for that by having a much higher axial or pull strength than nails (try to pull a screw straight out of timber just with a pair of pliers!). This can come at a cost however – screws are made of more brittle material than nails, and so if are used in situations where timber is likely to move and create shear pressure, screws might just snap where nails will hold.

An example of a great use for screws is putting down a deck – the main force decking timber will exert is wanting to bend and press up from the beam, and screws strong pulling force will keep decking strongly in place.

Nails

In general, nails are very long lasting and less brittle than screws. When we’re denailing old pieces of timber we can find nails over 100 years old that are still in great condition. Nails also come in a range of sizes, including very fine ones for detailed work. A fine nail that is inserted carefully can almost disappear in the surface of timber.

Nails provide a very strong fixing when a sheer force is applied, but far less support for axial pressure (consider that removing a nail from wood by pulling it directly out is mimicking how axial pressure will affect a nail joint; it’s far more difficult to pull a screw directly out without twisting it).

This can be considered if you’re making a piece of furniture that you may want to change something on or repair it later on – eg. a nailed on top will be easier to remove. The pressure of inserting a nail into timber is also a fair way of ensuring two pieces are well joined.

As with all hardware, the material your nails and screws are made from will make a big difference as to their strength/holding ability, but also will make a difference depending on your project. For example, a high strength steel nail will be great for structural work, but you may want a softer nail when assembling a piece of fine furniture.

Learning more about fixings for timber

If you’re interested to get some more hands on experience with glues, nails and screws, check out our wide range of courses. Our six week woodwork fundamentals course and our one day step stool course both use glue and other fixings and talk more in depth about why we use different ones.

We also stock a range of second hand hardware and fixings in store that you can buy by the gram. Visit us to see our selection and remove big-box hardware stores from your supply chain!