What hand tools do I need to start woodworking? - Part 2: Cutting and sawing

Once you’ve measured and marked your piece, most woodwork projects will require some kind of cutting to size and length. When we want to cut things by hand, we turn to the world of saws!

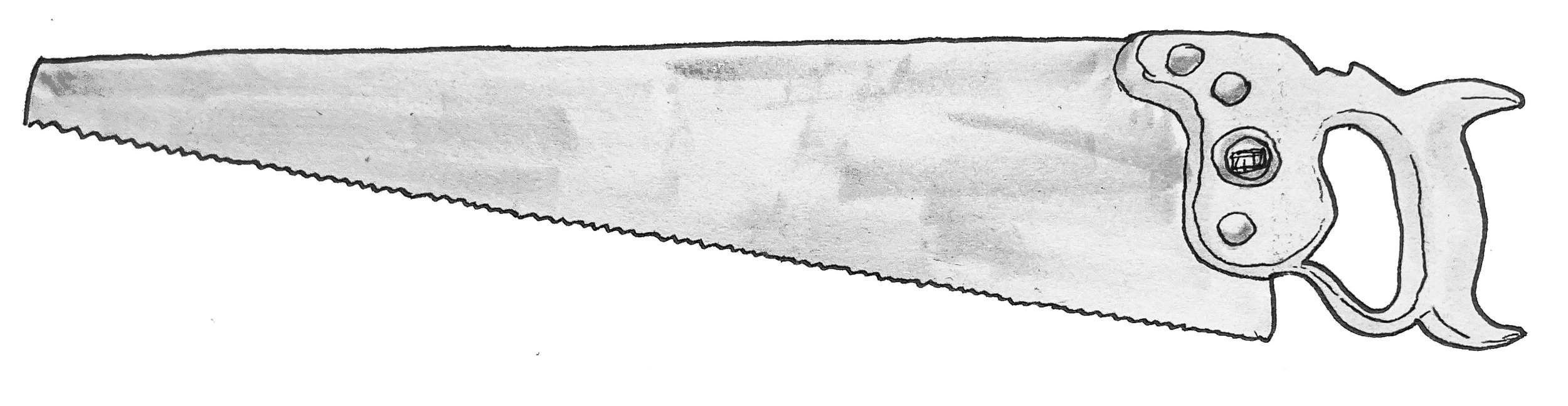

Crosscut saw

There are two standard saws used for cutting timber. The first, a crosscut saw, cuts across the grain of timber. The teeth are sharpened and shaped in such a way to make this a simpler task, and our arms are thankful for this invention!

Most saws you find in regular hardware stores will be cross-cut saws, as most trade and home saw use will be to cut a long piece of timber to length, and in doing so to cut across the grain.

Rip cut saw

The second standard saw we use in woodwork is a rip cut saw, which is used for cutting – or ripping – down along the grain of the wood. The teeth are shaped and sharpened differently to crosscut saws so that this job is much easier. If you have one of each and try to use them for the correct and incorrect sawing direction you will quickly find out why we have two different saws for these jobs!

Rip cut saws can be found in hardware stores, but you are more likely to find them through specialist tool retailers or second hand.

Good quality western-style saws like crosscut, rip cut, back saws and other specialty saws can be found in good condition and high quality second hand as well as new, and are often found at much more reasonable prices second hand.

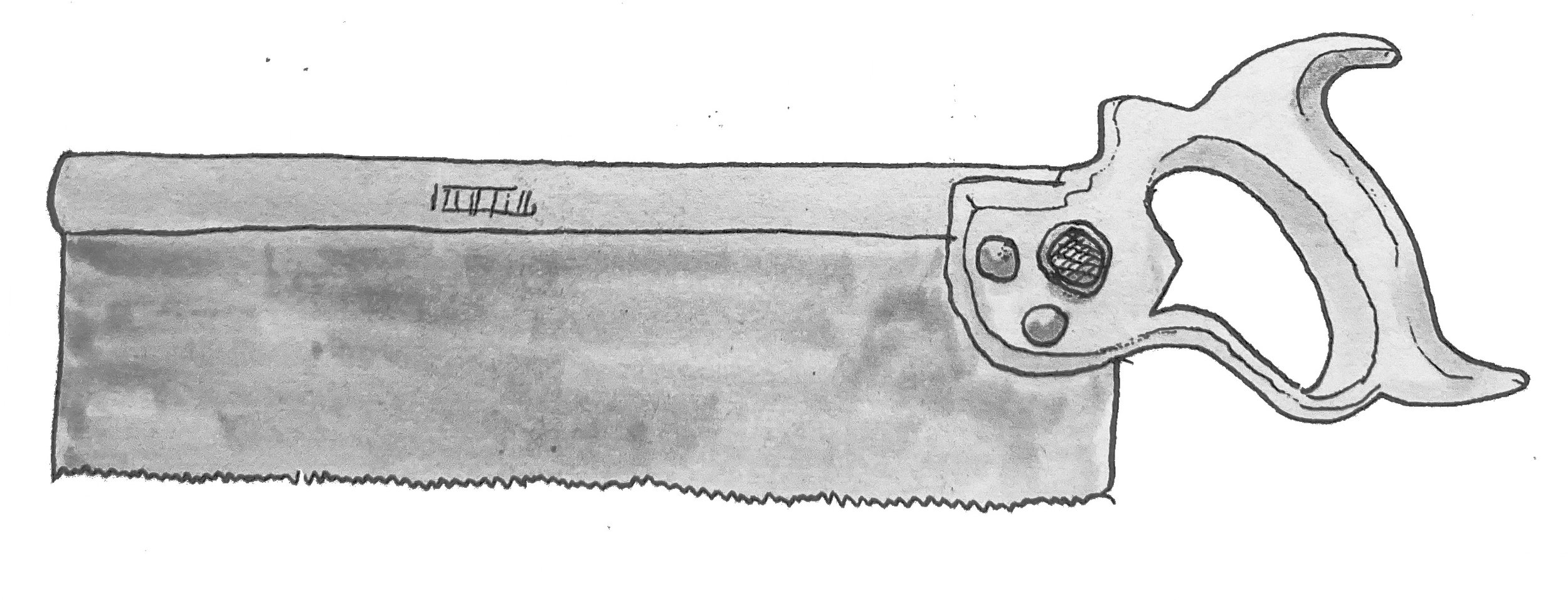

Back saw

A back saw is similar to the above saws, but has a finer blade (the big metal bit you saw with), and as a result has a strip of metal wrapped around the back of the blade to help keep it stable and straight while sawing. Back saws often have finer teeth than your standard cross and rip cut saws and are used for work where cleaner, more precise cuts are necessary such as cutting joinery.

Bow saw

Bow saws may look old fashioned, but are still a practical and useful tool for the hand-tool workshop. Not only this, but making your own bow saw is a fun and interesting job, and much easier than trying to make a more standard style of saw when you’re starting out.

There are lots of great tutorials out there for how to make your own bow saw, or you can pick one up for a bargain as they’re often left to the side of tool or garage sales.

Fret saw or coping saw

Fret saws have a very fine, thin blade inside a large C shaped frame. The combination of the frame and the fine saw blade allow you to easily pivot the saw around curves and tight bends so you can cut out curves and shapes easily.

There are many different designs of fret saws out there today, using all sorts of modern and high-strength materials to improve performance, but we still reckon the traditional steel fret saw of yesteryear does the job just fine!

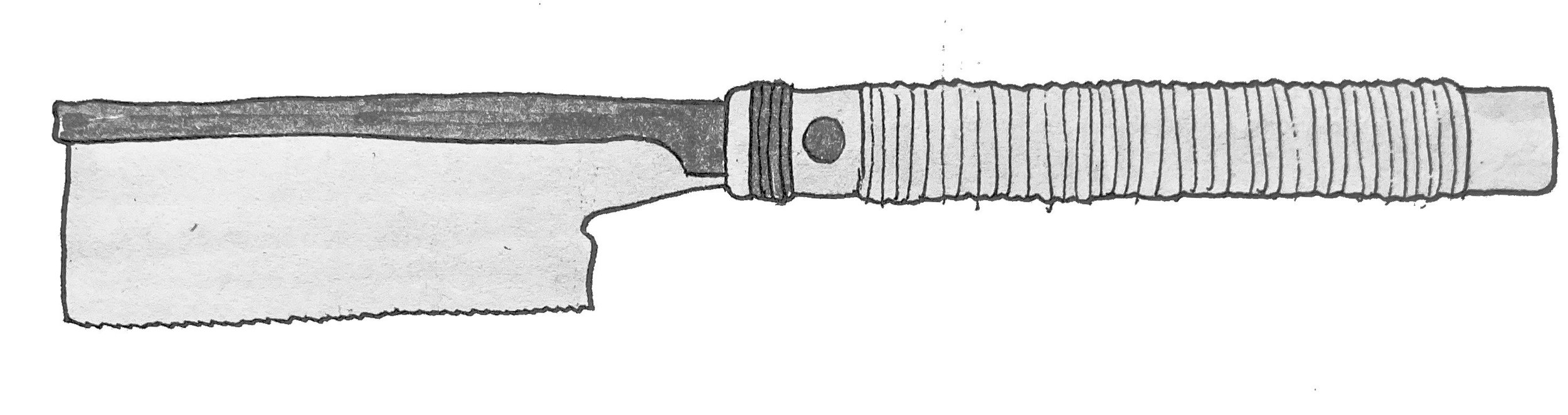

Pull saws, or japanese style saws

There are a whole range of Japanese-style saws, also known as pull saws. Japanese saws differ from western-style saws because they cut on the pull-stroke, rather than the push stroke. Because of this, the blade of pull saws can be much finer than western-style saws due to the pulling motion helping to keep the blade straight while cutting.

Japanese-style saws are a whole world unto themselves, and we have only just touched the surface of them here. You can find out more about the wide range of pull saws available through stores like Japanese Tools Australia.

Learning more about saws and sawing

If you’re interested to get some more hands on experience with the different kinds of saws that are out there, check out our short courses, including the 6 week Sawbench course or our one day Stepstool course, both of which have a range of different saw skills included.